Table of Contents

It’s 4 PM. You’re behind schedule, the team is fixing issues, and no one knows why half the tasks exist. The problem isn’t effort; it’s a broken process. Too much rework, too many steps, and little focus on what matters. Lean Project Management is designed to change that.

It shifts focus from doing more to doing better, spotting value, removing waste, and building smarter systems. The result? Less waste, more value, and a happier, more productive team. This blog will show you how Lean Project Management works, why it matters, and how to apply it in real-world situations across industries. Let’s dive in!

Table of Contents

1) What is Lean Project Management?

2) Why is Lean Project Management Important?

3) Principles of Lean Project Management

4) How to Implement Lean Project Management?

5) Improve Your Workflow with Lean Project Management

6) How to Measure Lean Project Success?

7) What are the Benefits of Lean Project Management?

8) Challenges of Lean Project Management

9) Popular Lean Project Management Tools

10) Conclusion

What is Lean Project Management?

Lean Project Management is a methodology that prioritises delivering maximum value to the customer while eliminating all forms of waste. Rather than simply checking off tasks, it focuses on meaningful outcomes while saving time, using resources efficiently, and reducing waste by cutting out anything that doesn’t add value.

It promotes flexibility, smooth workflow, and continuous improvement over rigid planning. The goal is to reduce delays, eliminate unnecessary steps, and make better use of your team’s time and energy. As a result, it allows teams to adapt quickly to change, without sacrificing quality.

Why is Lean Project Management Important?

Lean Management is important because it plays a key role in making businesses more efficient. It focuses on doing more with less, saving costs by cutting unnecessary steps and streamlining processes like production and transportation. By removing bottlenecks and empowering employees, companies can increase productivity and stay competitive.

Lean Management also elevates customer satisfaction by delivering value quickly and effectively. Moreover, it boosts employee engagement by involving everyone in problem-solving and improvement, thus creating a motivated workforce.

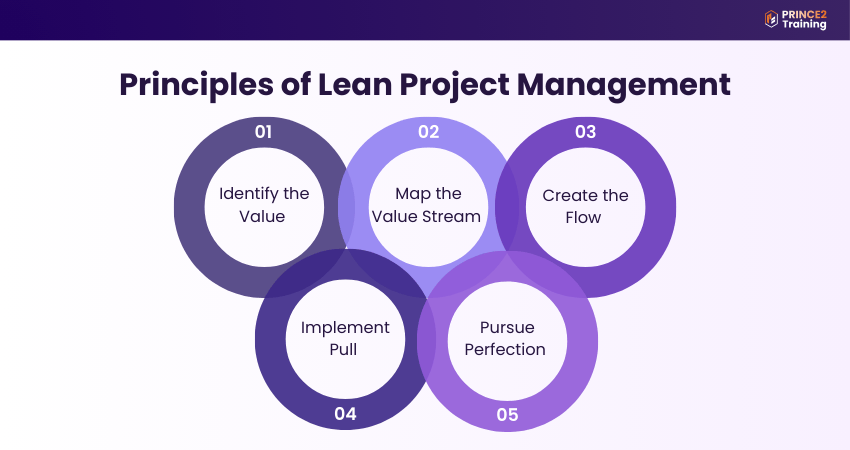

Principles of Lean Project Management;

Lean is based on five key principles. These steps help teams keep their focus on what really matters and avoid wasting time and effort. Let's check what those principles are:

1) Identify the Value

The first principle of Lean Project Management is to identify the value that matters most to your customers and stakeholders. This could be the feature of a product, a timely delivery, or a user-friendly solution. Anything that fails to contribute to the project's value will become a waste.

To Identify Value:

1) Engage directly with stakeholders for inputs

2) Understand their priorities and expectations

3) Define success based on their expectations

2) Map the Value Stream;

The next principle is to map out the steps clearly to visualise how your project delivers value. You can use Value Stream Mapping (VSM) to visualise your project workflow from the beginning to the end. After that, you need to compare it with the older version that focuses only on tasks that directly contribute to value.

This Step Uncovers:

1) Repetitive tasks and workflow slowdowns

2) Excessive or unwanted approvals

3) Where time, effort, or resources are being wasted

Power up your career with the gold standard in Project Management. Sign up for our PRINCE2® Certification now!

3) Create the Flow

After eliminating waste, the goal is to establish a smooth and continuous flow of work across the team. In Lean methodology, anything that causes delays, interruptions, or waiting is a barrier to productivity. Creating flow ensures tasks progress seamlessly without unnecessary delays or confusion.

Techniques to Ensure Flow:

1) Use visual tools to monitor progress

2) Limit the number of tasks in progress

3) Build and support cross-functional teams

4) Implement Pull

Instead of doing work in advance and hoping it will be used, Lean Project Management uses a pull system. This means work only starts when it is actually needed or a demand for it. This helps avoid overproduction and keeps resource usage in check.

This Avoids:

1) Burdening team members with too many tasks

2) Having too many tasks left unfinished

3) Spending time on tasks that aren’t needed

5) Pursue Perfection

Lean is not a one-time fix; it's a mindset rooted in continuous improvement. The final principle, known as Kaizen, transforms Lean into an ongoing journey. Even with an efficient workflow, your tools, team, and goals will evolve. That’s why it's essential to continuously refine how you work.

Tips for Continuous Improvement:

1) Have regular team meetings and check-ins

2) Collect feedback from both team members and customers

3) Review your workflow often to find new areas to improve

How to Implement Lean Project Management?

The beauty of Lean Project Management is its adaptability. It has been successfully implemented across diverse industries, each tailoring it to their specific needs. It is especially useful in industries where time, cost, and quality are closely connected and where small improvements can lead to big results. Here's how you can implement it:

1) Manufacturing

Lean Project Management has its roots in manufacturing, making it a perfect match for this environment. By focusing on cutting waste like excess inventory, overproduction, or waiting time, manufacturers can:

1) Increase productivity

2) Lower operational costs

3) Improve product quality

4) Reduce defects and rework

5) Simplify workflows and processes

6) Use space, labour, and materials more efficiently

2) Construction

In construction, time delays and material waste are frequent and costly. Lean Project Management helps improve planning, execution, and coordination to prevent inefficiencies. Implementing Lean in construction enables teams to:

1) Reduce costly delays and waiting periods

2) Minimise material waste and over-ordering

3) Apply just-in-time delivery to avoid clutter and storage problems

4) Create safer, more organised worksites

5) Deliver projects within budget and on time

3) Product and Software Development

Lean works well in product and Software Development areas. This is because teams in these sectors need to move fast, adapt quickly, and keep users at the centre of every decision. By using Lean principles, development teams can:

1) Focus on high-value features instead of doing everything at once

2) Reduce development cycles and speed up delivery

3) Continuously improve based on feedback

4) Eliminate unnecessary steps in the workflow

5) Align closely with customer needs and market changes

Learn the principles that turn project plans into project wins in our PRINCE2® Foundation Training - Register now!

How to Improve Your Workflow with Lean Project Management?

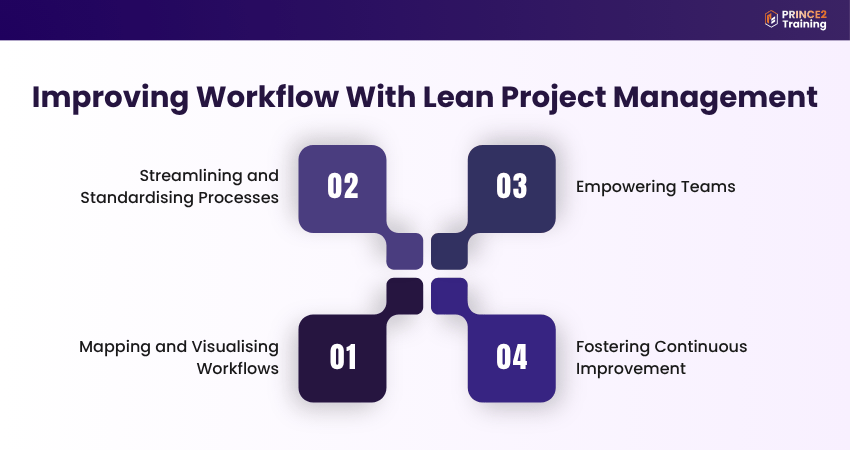

Improving your workflow through Lean Project Management means focusing on efficiency, consistency and continuous growth. Here's how you can ensure it:

1) Mapping and Visualising Workflows

A clear view of how tasks move throughout a project helps everyone stay on track. Using visual tools like boards or charts makes it easier to track progress, detect bottlenecks and improve processes in real time.

2) Streamlining and Standardising Processes

Consistency is key to achieving quality. This is why establishing standard procedures is vital for recurring tasks, as it reduces mistakes and simplifies onboarding for new team members. When everyone follows the same structure, the results become more predictable and reliable.

3) Empowering Teams

Lean Project Management values autonomy. Here, teams are encouraged to take responsibility and solve problems independently. This empowerment not only improves engagement but also encourages collaboration and innovation within the group.

4) Fostering Continuous Improvement

Ongoing improvement is at the heart of Lean Project Management. By regularly reviewing the workflows and refining methods, organisations can ensure steady progress and long-term efficiency.

How to Measure Lean Project Success?

Measuring success in Lean Project Management is about assessing how effectively value is delivered and waste is minimised.

1) Cycle Time: It tracks how long it takes to complete a task from start to finish. Shorter cycle times indicate smoother workflows and improved efficiency.

2) Throughput: This measures how many tasks are completed within a set time frame. Higher throughput reflects better productivity and resource use.

3) Lead Time: This represents the total time from when a request is made to when it’s delivered. Reducing lead time improves responsiveness and customer satisfaction.

4) Customer Satisfaction: It's evaluated through direct feedback, surveys or Net Promoter Scores (NPS). High satisfaction levels show the team is meeting or exceeding customer expectations.

5) Waste Reduction: This focuses on minimising delays, defects, and unnecessary work. Less waste means more value delivered with fewer resources.;

What are the Benefits of Lean Project Management?

Implementing Lean principles in Project Management has several impactful benefits. Here are the key benefits:

1) Boosted Efficiency;

1) Streamlines processes to reduce time spent on each task

2) Eliminates unnecessary steps and distractions

3) Keeps teams focused on value-adding work

4) Promotes continuous improvement for sustained performance

5) Utilises team capacity wisely without overburdening them

2) Reduced Waste

1) Identifies and removes tasks that don’t add value

2) Minimises overproduction and unnecessary work

3) Reduces rework by improving quality from the start

4) Avoids time spent on unused or low-priority tasks

5) Makes better use of materials and tools

3) Enhanced Customer Satisfaction

1) Delivers what customers truly need instead of what's planned

2) Responds quickly to changing customer demands

3) Ensures higher quality outcomes with fewer defects

4) Builds trust through consistent and clear communication

5) Involves customers early and often in the process

4) Stronger Team Collaboration;

1) Encourages open communication and knowledge sharing

2) Builds cross-functional teams that work better together

3) Reduces confusion about roles and responsibilities

4) Promotes shared ownership of outcomes

5) Involves the team in problem-solving and improvements

Challenges of Lean Project Management;

While Lean Project Management has many benefits, putting it into practice can be tricky. Here are some of the common challenges you may face:

1) Resistance to Change: People used to traditional ways of working may feel unsure or uncomfortable with Lean’s new approach.

2) Not Enough Training: If the team doesn’t fully understand Lean, they may apply it incorrectly or miss its real purpose.

3) Focused on Short-term Goals: Lean’s focus on fast delivery can sometimes make teams forget to think about the bigger picture.

4) Incomplete Adoption: Some teams try Lean tools like Kanban but don’t follow Lean thinking, which leads to poor results.

5) Lack of Proper Support: Without strong leadership guidance, it can be hard to make Lean work across the whole organisation.

6) Poor Communication: If teams don’t talk openly or share feedback, it will be difficult to spot problems and improve processes.

Master the art of agile delivery within a proven project framework - Register for our PRINCE2 Agile® Practitioner Training now!

How to Implement Lean Project Management?

The beauty of Lean Project Management is its adaptability. It has been successfully implemented across diverse industries, each tailoring it to their specific needs. It is especially useful in industries where time, cost, and quality are closely connected and where small improvements can lead to big results. Here's how you can implement it:

1) Manufacturing

Lean Project Management has its roots in manufacturing, making it a perfect match for this environment. By focusing on cutting waste like excess inventory, overproduction, or waiting time, manufacturers can:

1) Increase productivity

2) Lower operational costs

3) Improve product quality

4) Reduce defects and rework

5) Simplify workflows and processes

6) Use space, labour, and materials more efficiently

2) Construction

In construction, time delays and material waste are frequent and costly. Lean helps improve planning, execution, and coordination to prevent inefficiencies. Implementing Lean in construction enables teams to:

1) Reduce costly delays and waiting periods

2) Minimise material waste and over-ordering

3) Apply just-in-time delivery to avoid clutter and storage problems

4) Create safer, more organised worksites

5) Deliver projects on time and within budget

3) Product and Software Development

Lean works well in product and Software Development areas. This is because its teams need to move fast, adapt quickly, and keep users at the centre. By using Lean principles, development teams can:

1) Focus on high-value features instead of doing everything at once

2) Reduce development cycles and speed up delivery

3) Continuously improve based on feedback

4) Eliminate unnecessary steps in the workflow

5) Align closely with customer needs and market changes

Popular Lean Project Management Tools

Lean Project Management tools provide structure for how improvements are planned, tested, and implemented. They serve as essential instruments for turning Lean principles into practical, measurable outcomes. Here are some of the most widely used Lean tools:

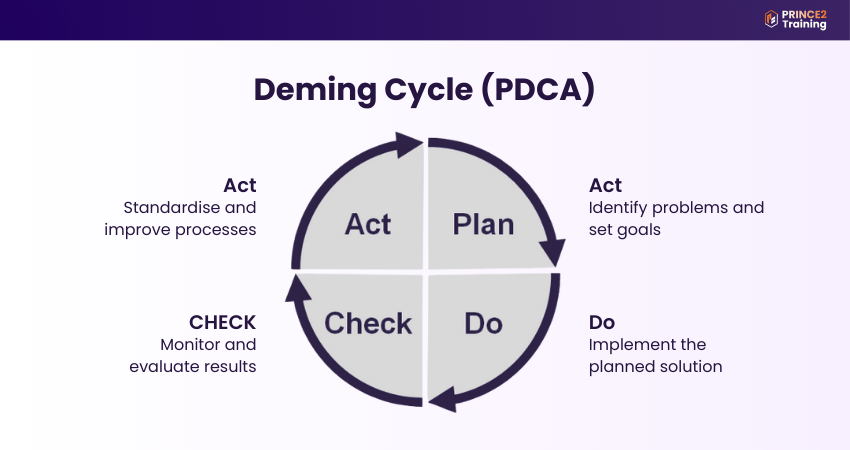

1) Deming Cycle (PDCA)

Also known as the Plan-Do-Check-Act (PDCA) cycle, the Deming Cycle is a foundational tool for continuous improvement. It enables teams to break down changes into manageable steps, implement them incrementally, and evaluate outcomes systematically.

How it Works:

1) Plan: Set clear goals and create a strategy based on real data

2) Do: Try out the changes on a small scale

3) Check: Measure the results to see what worked and what didn’t

4) Act: Adopt successful improvements and refine areas that need enhancement

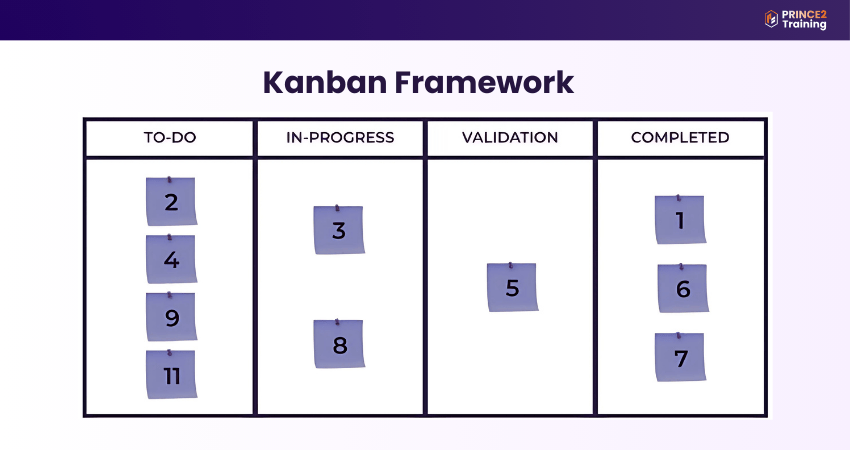

2) Kanban Framework;

Kanban is a visual workflow management system that helps teams track work as it moves through different stages. It uses columns like “To Do,” “In Progress,” and “Done.” It supports Lean principles by making work visible and manageable.

Key Benefits of Kanban:

1) Shows project status in real time

2) Helps spot bottlenecks quickly

3) Encourages focus by limiting Work In Progress (WIP)

4) Works well with both physical boards and digital tools

3) Lean Six Sigma Techniques

Lean Six Sigma merges the waste-reduction principles of Lean Project Management with the quality control methods of Six Sigma. These powerful, data-driven approach is used to solve complex problems, enhance process efficiency and maintain high-quality outcomes.

Common Tools Include:

1) Define, Measure, Analyse, Improve, and Control (DMAIC)

2) Root Cause Analysis (RCA)

3) Control Charts and Statistical Process Control (SPC)

4) Failure Mode and Effects Analysis (FMEA)

4) DMEDI Model;

The DMEDI model stands for Define, Measure, Explore, Develop, and Implement, and is basically a Lean Six Sigma tool used primarily for designing or improving new processes or products. It offers a step-by-step method to improve processes or build better products from scratch.

Each Stage Involves:

1) Define: Set clear goals and identify what the customer needs

2) Measure: Gather data to understand how things currently work

3) Explore: Brainstorm and assess different possible solutions

4) Develop: Build and test the most promising ideas

5) Implement: Put the solution into action and monitor the results

Conclusion

As a team or organisation, adopting Lean Project Management can transform the way you work. It allows you to cut down on waste, focus on what your customers truly value, and create more efficient, responsive workflows. Instead of getting caught up in unnecessary tasks, you can centre your efforts on what really drives results. Thus, Lean isn’t a one-time fix. It is a shared journey of growth.

Our PRINCE2® Practitioner Training will bring together your leadership skills with a gold standard Project Management methodology – Sign up now!

Back

Back

Back to

topics

Back to

topics